Turbo Dust Cleaner

From Turbo Challenger® to Turbo Dust Cleaner®

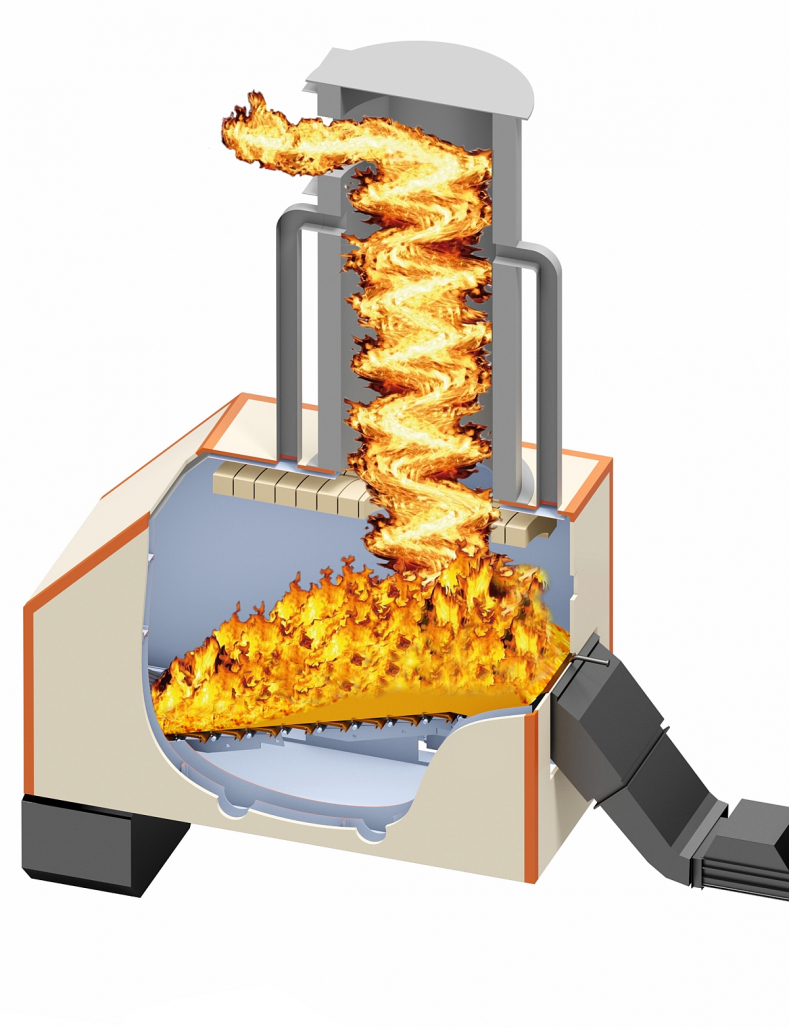

Our Turbo Challenger® has proven its exceptional properties in a wide variety of applications. Due to the combination of a hydr. feed grate furnace with cyclone fluidised bed combustion, the thermal utilisation of very demanding biomass, such as green waste, forest residue, contaminated bark, uncontaminated waste wood, etc., is possible without any problems. These properties, which are also very impressive from an economic point of view, can be demonstrated in a wide variety of systems installed throughout Europe.

Thanks to special design measures in the combustion chamber, the Turbo Dust Cleaner® is able to clean the dust from the flue gas immediately in the hot gas path. This results in the following properties, which are very important for the operation of a biomass heating system:

- The flue gases coming out of the combustion chamber of the boiler system, which are very abrasive, are charged with cleaned flue gases. As a result, system parts such as boiler tubes and other components are subject to much less wear.

- The soiling of the heat exchangers decreases considerably. This increases the service life and additionally increases the energy output of the boiler system.

The fly ash located in the hot area of the boiler system is fed through the system to the grate ash. The filter-ash-to-grate-ash ratio, which can be as high as 1:10, can save on considerable disposal costs. - The ash separated in the hot area of the Turbo Dust Cleaner®, is fed, free of heavy metals, directly to the grate ash and can be disposed cost-effectively.

The new Turbo Dust Cleaner®: even more efficient – even more universal – even more cost-effective

Share post

Interested? – Contact us!

Get in touch with us – we will be happy to advise you on your plans and implement your projects!